Destination Innovation: Sustainable Plastic Alternatives Are in Reach

The European Union implemented a plastic waste tax at the start of 2021, with the express purpose of driving a shift away from traditional plastic product packaging. Closer to home, Walmart’s current published sustainability goals set specific supplier expectations for packaging, some with time horizons as close as 2025. And even as legislation and retailers apply top-down pressure on brands to prioritize sustainability, rising consumer sentiment amplifies the same urgent call. In other words, sustainable packaging innovation is not a goal for the future. It’s a mandate for the present.

Achieving more sustainable standards in CPG will require a multi-pronged effort encompassing overall packaging reduction and improvements in reusability and recyclability, to be sure. But given the prevalence of single-use plastics in our industry and their outsized environmental impact, we at 3D Color have made reducing plastic one of our leading priorities, with specific focus on the enormous, immediate opportunity of molded fiber.

WHAT IS MOLDED FIBER AND WHAT CAN IT DO?

Molded fiber is a packaging solution that shapes plant-based fibers into forms using heated molds. Commonly used plant fibers include virgin wood pulp or recycled paper (also known as kraft) and, in our case, bamboo and bagasse (a sugarcane byproduct).

We prefer bamboo and bagasse because they are readily renewable, fast-growing plants that can be harvested four to six times per year. This makes them a more sustainable solution and helps combat the deforestation problems associated with tree-based fibers. All of our raw material sources are certified by the US Forest Stewardship Council (FSC).

In our drive to unlock even more sustainable options, we’re currently involved in trials using agricultural waste such as wheat, straw, reed and palm fibers in packaging applications. We also use recycled corrugated kraft derived from post-industrial or post-consumer paper waste.

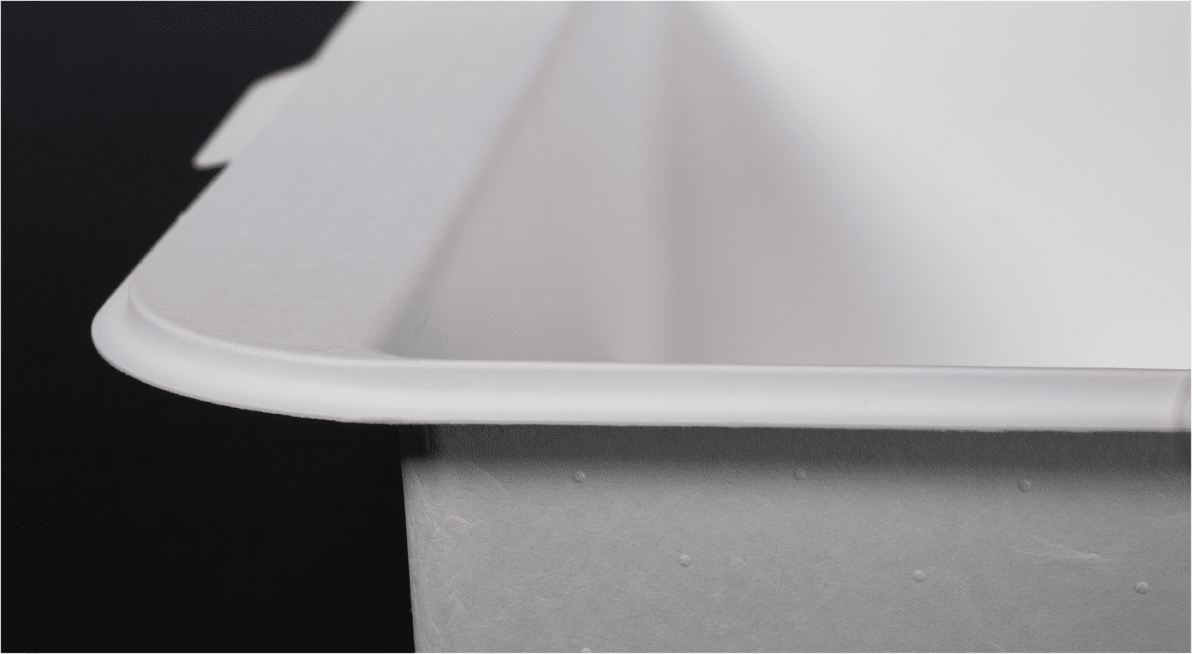

Sophisticated plant-derived molded fiber substrates are now suitable for many of the needs traditionally met by plastic, such as custom-formed packaging trays and inserts. Innovation is well underway toward sustainable food-safe coatings that will expand potential applications even further.

In our drive to unlock even more sustainable options, we’re currently involved in trials using agricultural waste such as wheat, straw, reed and palm fibers in packaging applications. We also use recycled corrugated kraft derived from post-industrial or post-consumer paper waste.

Sophisticated plant-derived molded fiber substrates are now suitable for many of the needs traditionally met by plastic, such as custom-formed packaging trays and inserts. Innovation is well underway toward sustainable food-safe coatings that will expand potential applications even further.

A PROVEN SOLUTION FOR SCALE.

While high-performance molded fiber is somewhat new to consumer packaged goods, it’s a common choice in consumer electronics when leading brands want both beautiful design and sustainability. At 3D Color, we’ve already established sourcing and manufacturing partnerships that enable us to achieve global-scale production in this sustainable material.

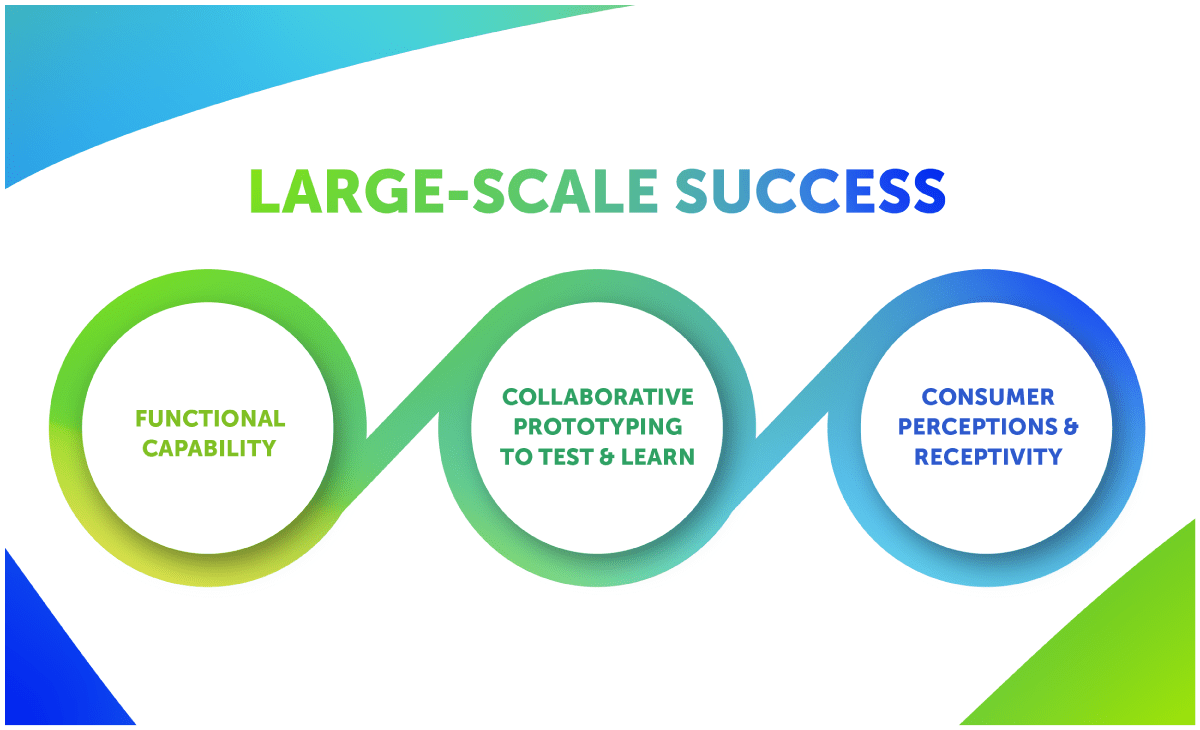

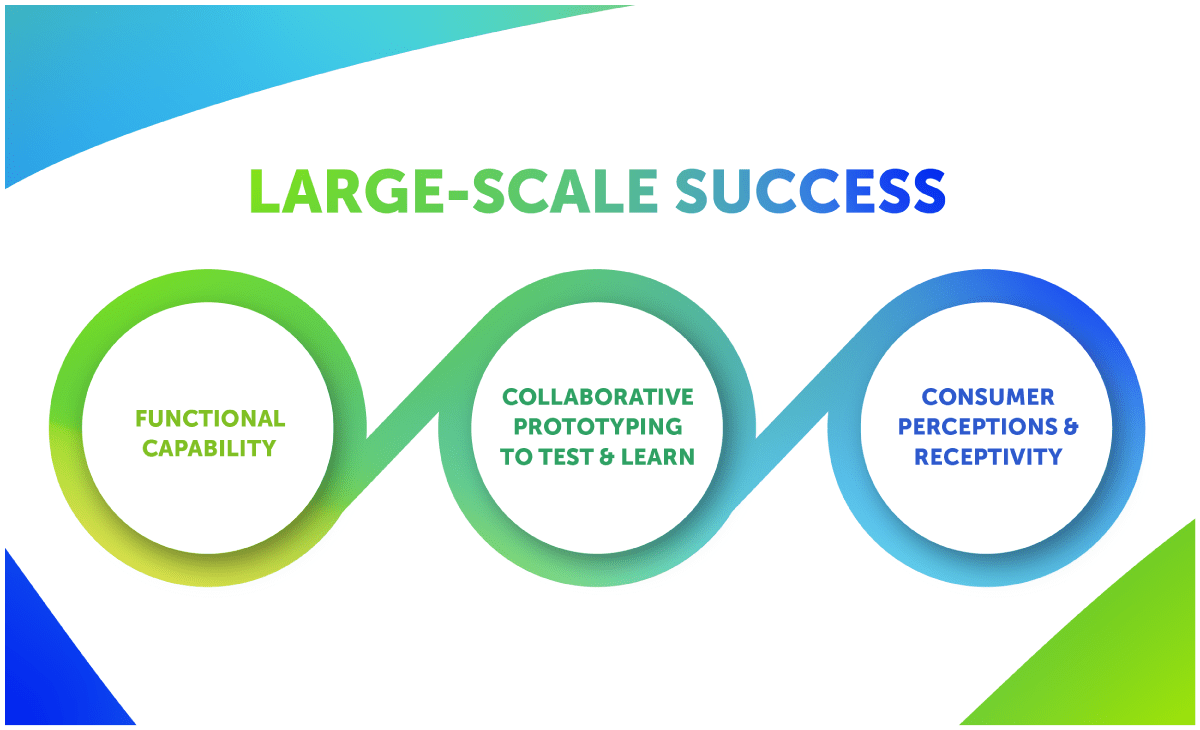

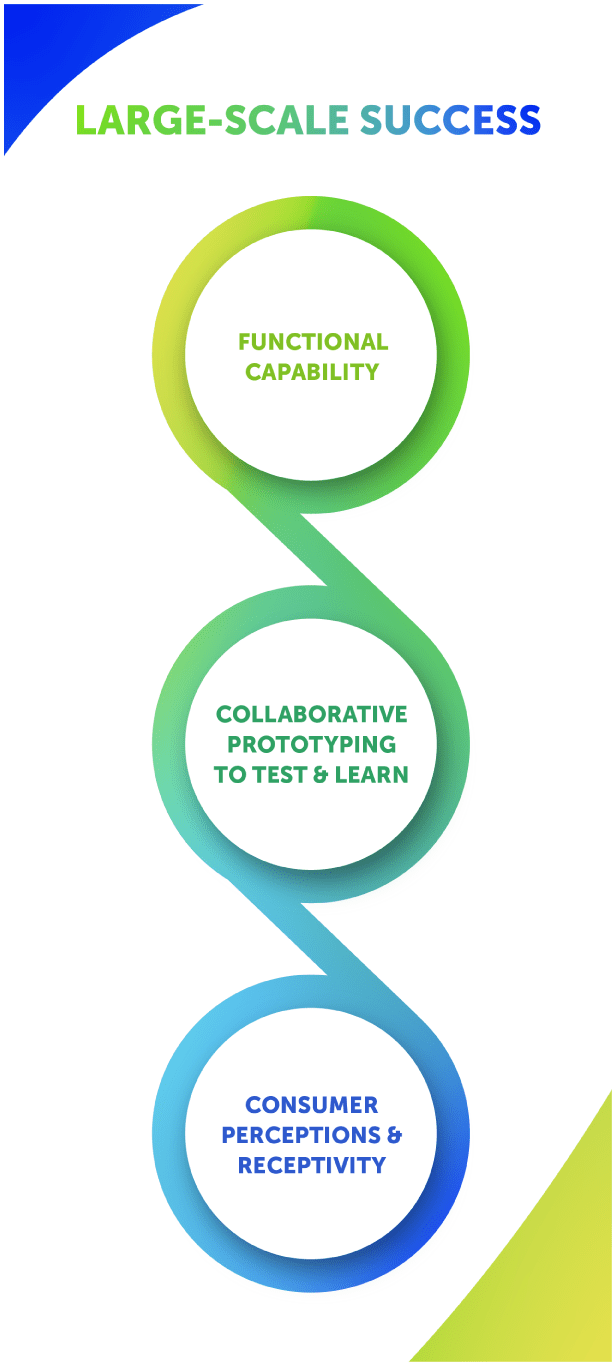

As with any innovation, large-scale success will depend not only on functional capability, but also on consumer perceptions and receptivity. We’re helping to pave that path by partnering with some of the industry’s most visionary brands to build prototypes for consumer testing.

NEW MATERIALS REQUIRE NEW WAYS OF THINKING.

In a historically plastic-based business, the technical world of materials innovation can feel like a black box. The packaging suppliers whom brands have traditionally relied on may lack the expertise (and, perhaps, the motivation) to drive exploration into this unknown territory. Prototyping specialists, by contrast, have long been in the business of tinkering and experimenting to produce forms and structures that have never been seen before. Who better to guide brands in the quest for more sustainable solutions? With the right partners on board, breakthrough packaging innovation may be nearer on the horizon than you’d think.

NEW MATERIALS REQUIRE NEW WAYS OF THINKING.

In a historically plastic-based business, the technical world of materials innovation can feel like a black box. The packaging suppliers whom brands have traditionally relied on may lack the expertise (and, perhaps, the motivation) to drive exploration into this unknown territory. Prototyping specialists, by contrast, have long been in the business of tinkering and experimenting to produce forms and structures that have never been seen before. Who better to guide brands in the quest for more sustainable solutions? With the right partners on board, breakthrough packaging innovation may be nearer on the horizon than you’d think.

NEW MATERIALS REQUIRE NEW WAYS OF THINKING.

In a historically plastic-based business, the technical world of materials innovation can feel like a black box. The packaging suppliers whom brands have traditionally relied on may lack the expertise (and, perhaps, the motivation) to drive exploration into this unknown territory. Prototyping specialists, by contrast, have long been in the business of tinkering and experimenting to produce forms and structures that have never been seen before. Who better to guide brands in the quest for more sustainable solutions? With the right partners on board, breakthrough packaging innovation may be nearer on the horizon than you’d think.

Plastic reduction through materials innovation will be a defining strength of tomorrow’s winning brands. Those that rise to this challenge will be positioned to excel across multiple dimensions of success: retailer preference, consumer preference, regulatory compliance and good corporate citizenship.

At 3D Color, our team of strategists, engineers and designers stands ready to assist in future-proofing your packaging. If you’d like to continue the conversation, please reach out to me or clientsuccess@3dcolor.com to start a conversation.

Plastic reduction through materials innovation will be a defining strength of tomorrow’s winning brands. Those that rise to this challenge will be positioned to excel across multiple dimensions of success: retailer preference, consumer preference, regulatory compliance and good corporate citizenship.

At 3D Color, our team of strategists, engineers and designers stands ready to assist in future-proofing your packaging. If you’d like to continue the conversation, please reach out to me or clientsuccess@3dcolor.com to start a conversation.