More Than “Just a Comp”: How the Right Prototype Process Can Drive Efficiency, Elevate Quality and Create a Lasting Impression

In the course of packaging development, the “big reveal” of the first professionally produced prototype can be a magical moment. Countless hours of research and strategy, design exploration and refinement come to fruition in a true-to-life package you can finally touch and feel. But too often, marketers and design partners think of ordering comps as a straightforward box to check in the packaging development workflow. Instead, we should recognize comp production as an important value-add phase that can profoundly influence the path of a project, and ultimately the success of a product.

THE COMP PROCESS CAN INFORM, INSPIRE AND ELEVATE FINAL CREATIVE EXECUTION.

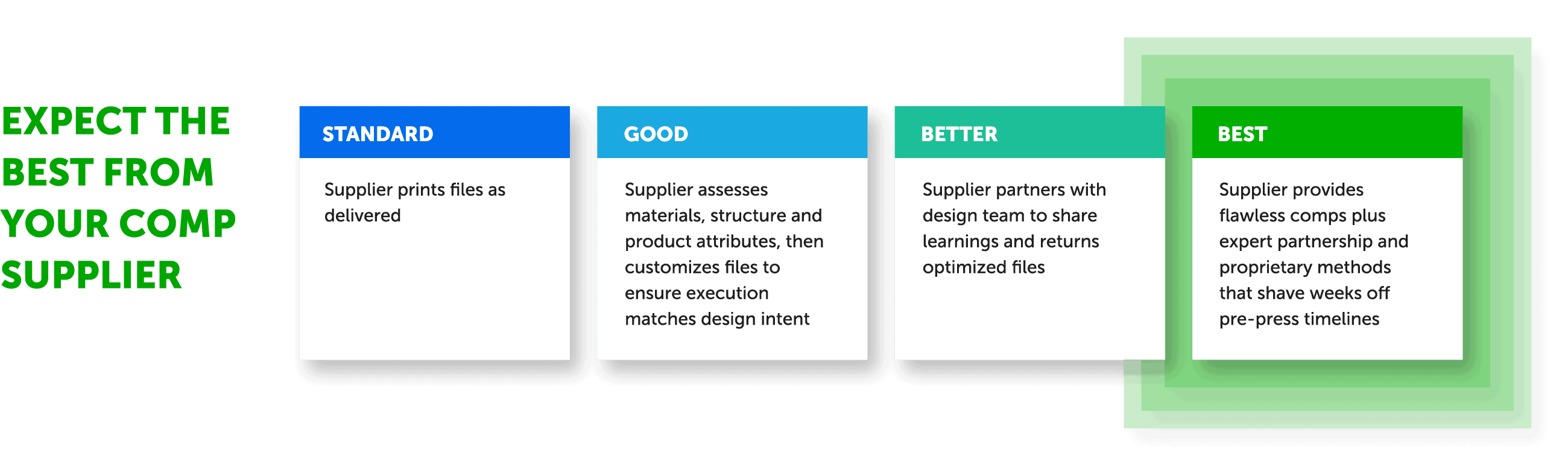

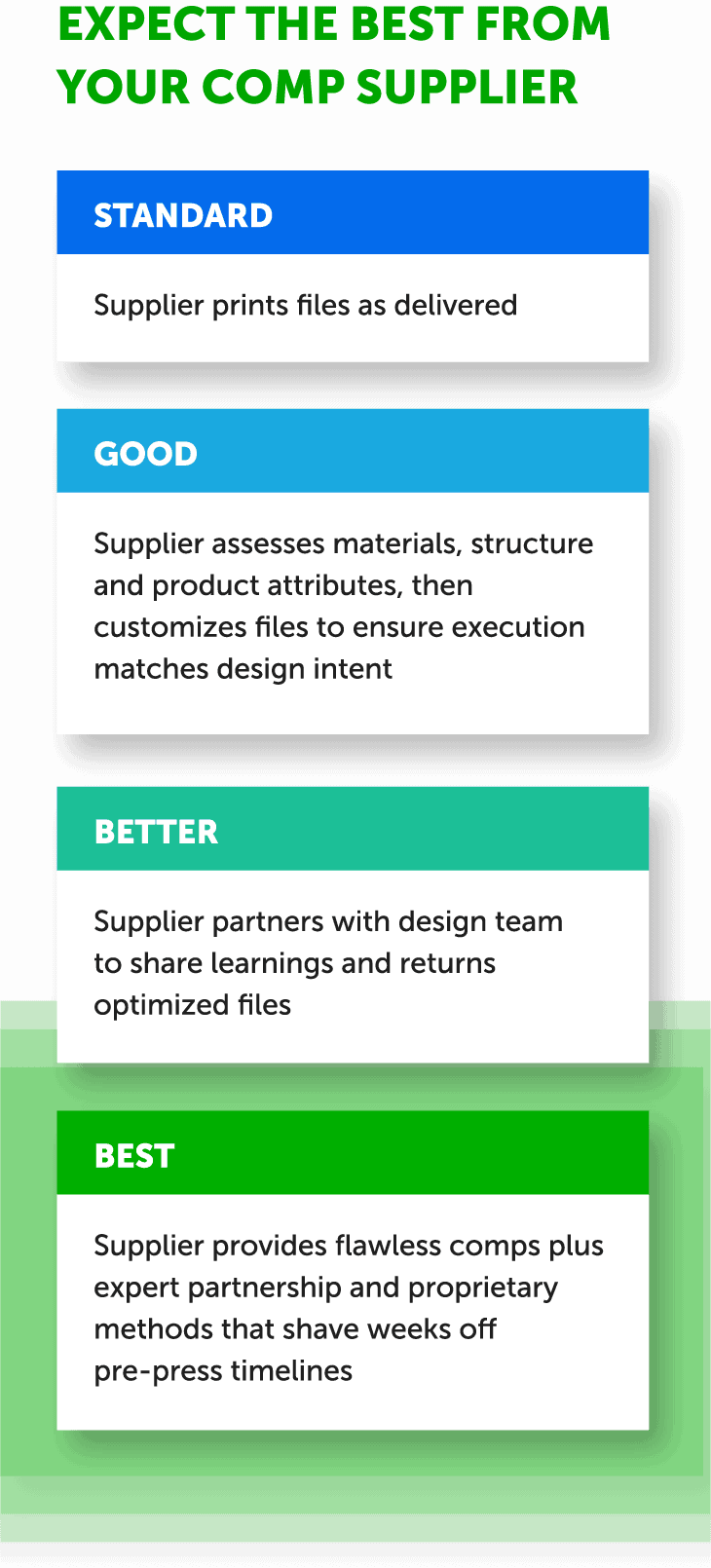

Many standard comp suppliers follow a WYS/WIP model: “What you send is what I produce.” While this approach may seem to boost efficiency, it’s likely to yield mediocre quality. More importantly, a transactional model misses the opportunity for collaboration and knowledge-sharing between design teams and experts in creative execution.

A skilled comp supplier will carefully consider the provided files in the context of the materials, packaging structure and product attributes at hand, and propose ways to optimize the files to more effectively meet the design target. As an example, matching a brand’s signature color may require different production files on a white substrate than on clear. And if the product inside the package is colored, yet more refinement is required. Ideally, the comp supplier will share these insights — and even the optimized files — back to the original design/production team. This knowledge-sharing step can elevate quality, streamline pre-press and set the stage for success in full-scale production.

A NOTE ABOUT TIMING

Coordinating comp production is logistically complex, and often falls in the middle of high-pressure product launch timelines. It’s no wonder “the fastest” is often mistaken for “the best.” A top-tier prototyping house, however, will work with you to minimize trade-offs, delivering both sophisticated partnership and the speed-to-market your business demands.

A GREAT COMP KEEPS IT REAL.

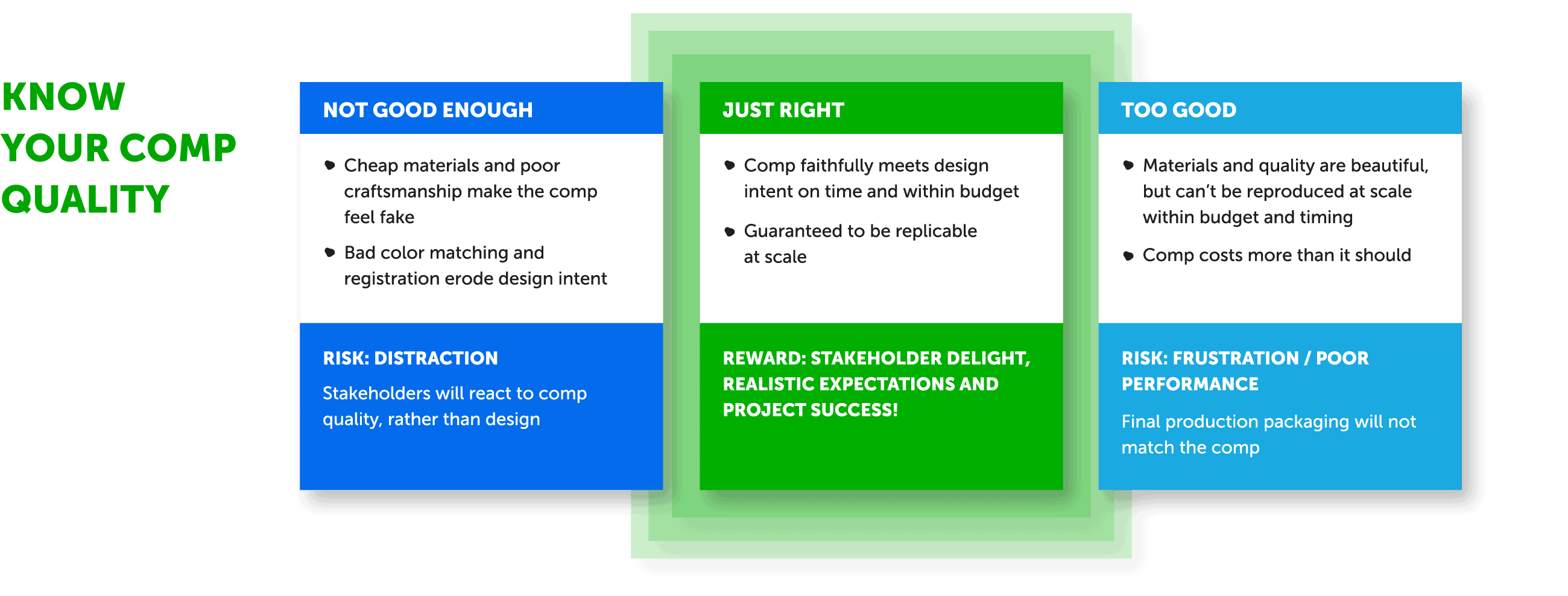

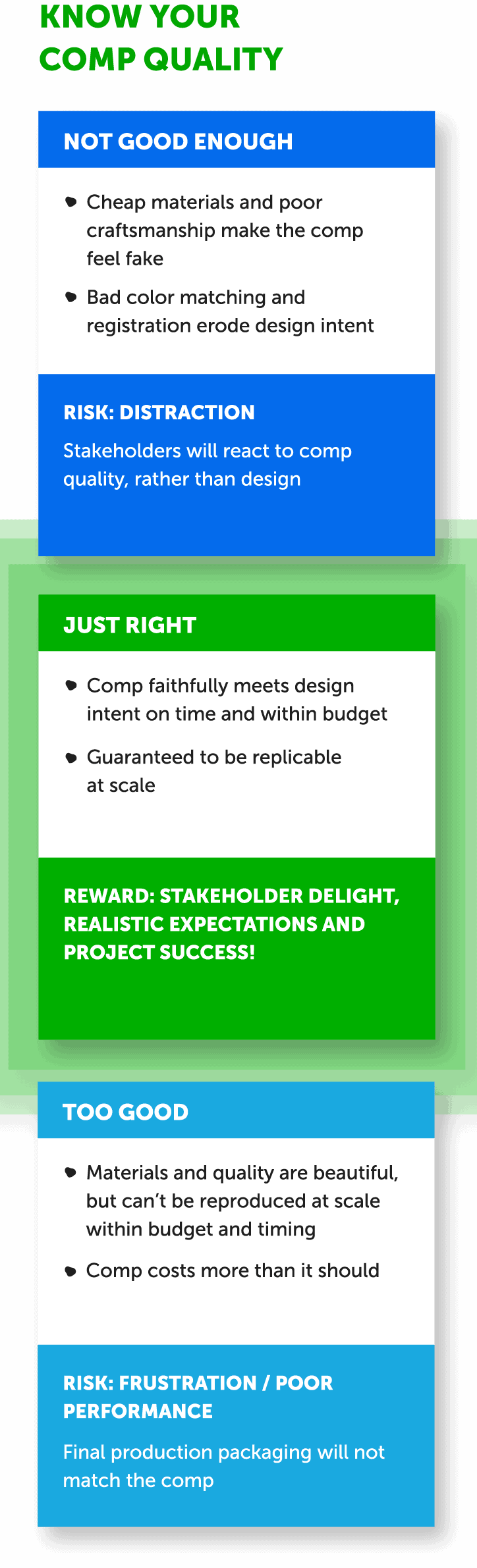

We’ve already discussed the value of a good process, but what about the prototype itself? Whether being used as a tool for consumer research, executive alignment or retailer sell-in, comps are quite literally the front lines of a package’s introduction to the world. That’s why it’s essential that your comps hit the bullseye of design intent. Quality issues like bad color matching or poor registration distract from the impression of value and can easily derail a mission-critical conversation. On the opposite end of the spectrum, a comp that’s “too good” also poses risk, setting an expectation that can’t be matched in full-scale production. “Too good” comps are particularly problematic in a research setting, where they might generate false positive data surrounding intent-to-buy or price expectations.

THE RIGHT PARTNER CAN MAKE ALL THE DIFFERENCE.

Is your comp process a tactical race to meet deadlines, or a strategic development phase intended to add meaningful enterprise value? The answer may well depend on the supplier you entrust with your project. At 3D Color, we approach each initiative with advanced technical expertise, unique proprietary tools and processes, and genuine creative passion for design — all with the goal of exceeding your expectations, on time and within budget. If you’re interested in learning more, reach out to me or clientsuccess@3dcolor.com to start a conversation.